Superway Electric Coolant Pump Assists BTMS

The importance of battery thermal management system is self-evident. In order to ensure the power battery maintain the best working condition under different working conditions, Superway has launched a new generation of electric water pumps to help the development of the new energy vehicle industry with excellent performance and intelligent control.

Features

Intelligent start, precise control

Superway electric water pump has flexible start protection function and supports slow start mode, which can effectively reduce the impact when the motor starts and extend the service life. At the same time, the water pump adopts a worm motor with speed regulation and PWM duty cycle control, which can adjust different operating speeds according to needs, thereby optimizing power output and improving system energy efficiency.

Multiple security protections

Fault feedback protection - real-time monitoring of the operating status of the water pump, accurate feedback of abnormal information, and convenient maintenance and management.

Overvoltage and undervoltage protection - automatically adjust the operating status to avoid voltage fluctuations from damaging the equipment.

Stall protection - effectively prevent damage to the water pump caused by foreign matter blocking, ensuring long-term stable operation.

Low-noise operation, comfortable experience

New energy vehicles have increasingly higher requirements for NVH (noise, vibration and harshness). Superway electric water pumps use advanced noise reduction technology to ensure efficient operation while maintaining low noise levels, creating a quieter environment for the cockpit and passenger compartment.

Technical Specification

|

Pump series No.

|

Range of lift H(m) |

Recommended

flow range (L/h) |

Inlet/Outlet (mm) |

Voltage classes (v) |

|

EP100-1 |

2~13 |

800~2000 |

ø 20 / ø 25 / ø 38 |

24V |

|

EP100-2 |

2~10 |

800~2000 |

ø 20 / ø 25 / ø 38 |

12V |

|

EP200-1 |

2~10 |

2000~5000 |

ø 38 |

12V / 24V |

|

EP200-2 |

10~23 |

600~2500 |

Ø 38 / ø 25 |

12V / 24V |

|

EP200-3 (D series) |

10(11)~21 |

1500-3000 |

ø 38 |

24V |

|

EP200-3 (E series) |

2~10(11) |

2000~6000 |

ø 38 |

24V |

|

EP200-3 (X series) |

10(11)~22 |

1500-3000 |

ø 25 |

24V |

|

EP200-3 (X series upgrade) |

10(11)~23 |

1500-3000 |

ø 38 / ø 25 |

24V |

|

EP200-4 |

3~10 |

2000~6000 |

ø 38 |

24V |

|

EP300 |

10~26 |

1000~4000 |

ø 25 |

24V |

|

EP400 |

10~31 |

1000~4000 |

ø 25 |

24V |

|

EP400 Chuck plate |

10~31 |

1000~4000 |

ø 25 |

24V |

|

EP1000 |

11~20 |

4000~12000 |

ø 38 |

24V |

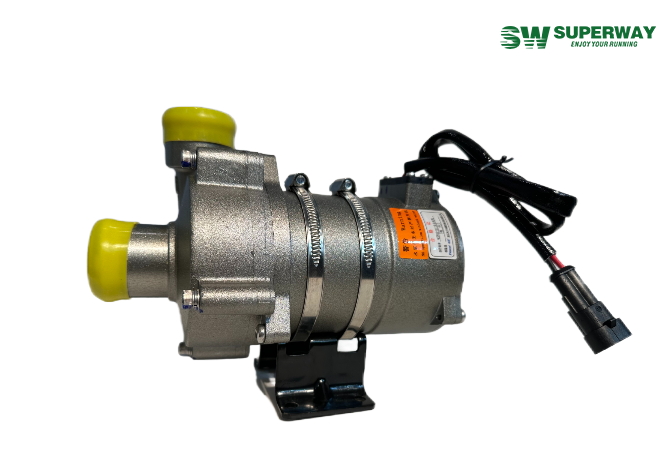

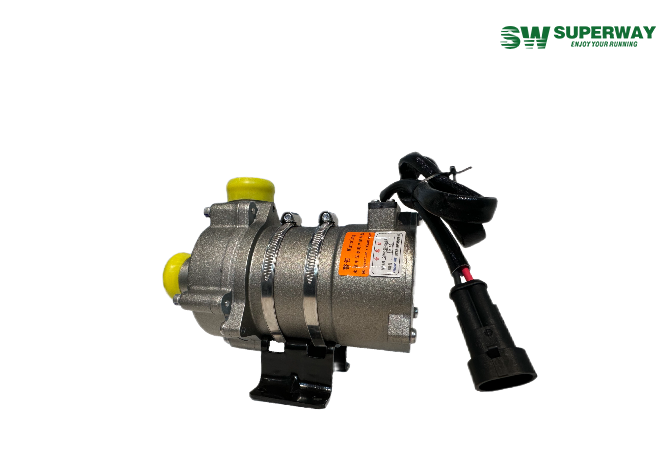

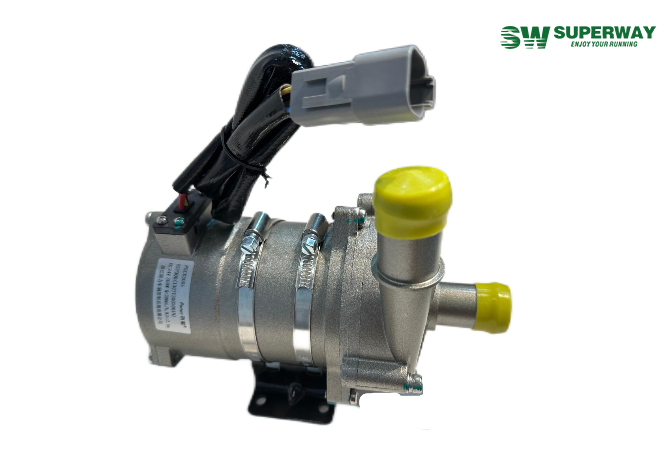

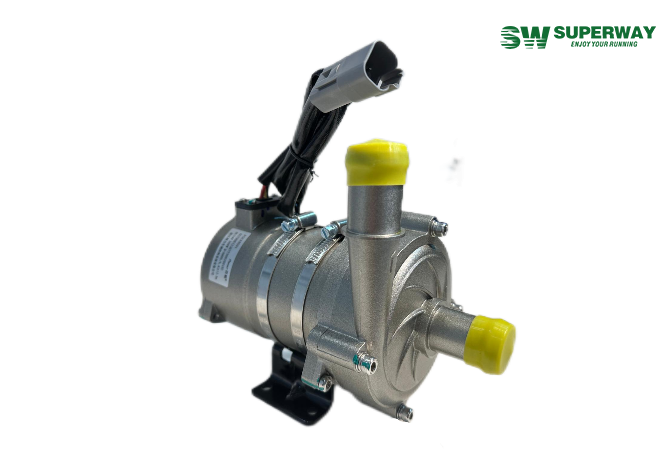

Photos

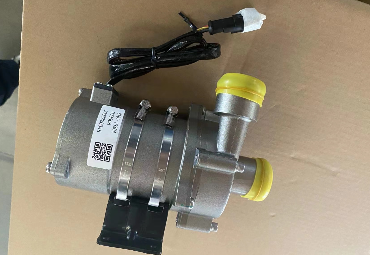

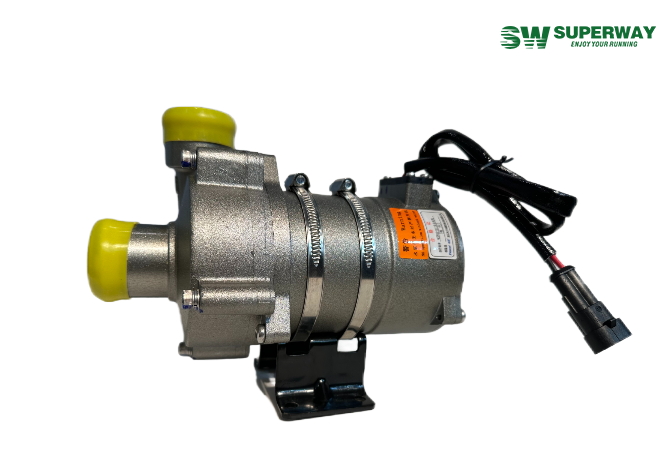

180w Coolant pump used in SEI system

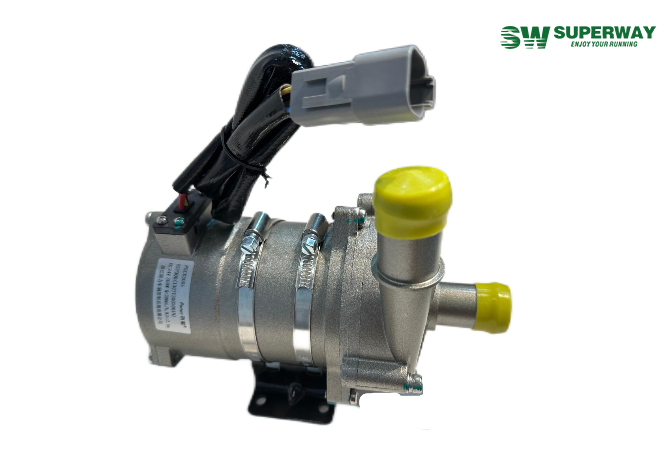

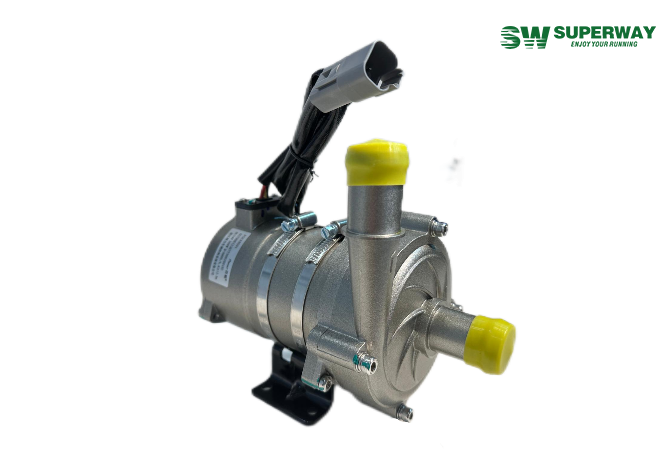

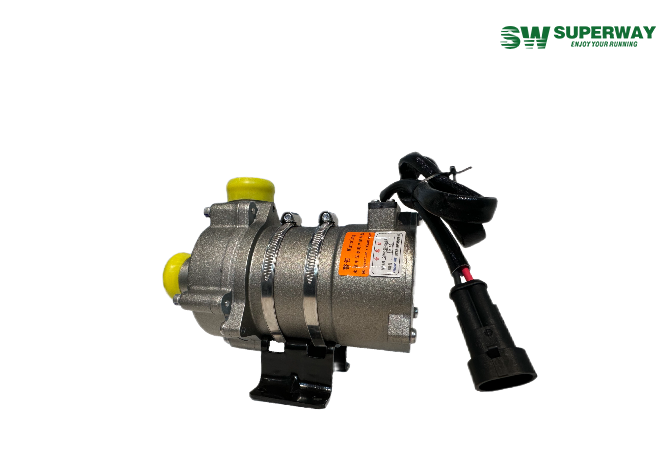

240w coolant pump delivery with AC system

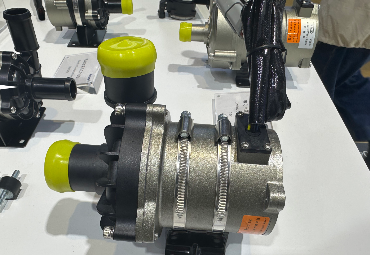

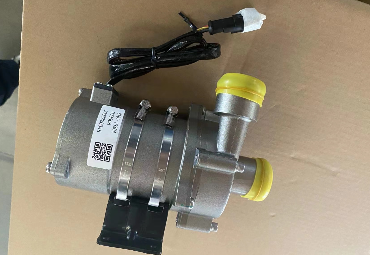

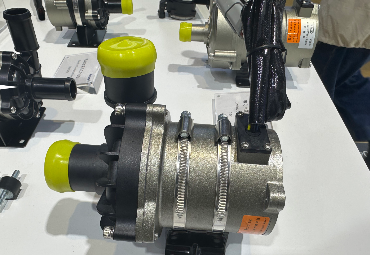

Coolant pump display

Leave a Reply

Your email address will not be published. Required fields are marked *